A dehydrator is a food processing appliance that uses controlled heating and continuous airflow to remove moisture from food products. Through moisture removal, food is preserved for an extended period while retaining its original flavor and nutritional value. Food dehydrator machines have a large scope in the food industry for the processing of fruits, vegetables, herbs, spices, and other food items without the use of chemical preservatives.

Applications of the Food Dehydrator Machine:

A food dehydrator machine is commonly utilized in the food processing industry to improve shelf life and preserve the flavor, texture, and nutritional value of products.

Fruit Processing Industry

Food dehydrator machines are frequently employed to dry fruits, including apples, bananas, mangoes, pineapples, grapes, and berries. Dehydrated fruits can be found in snacks, breakfast cereals, baked goods, and health foods. This application also offers a means to reduce post-harvest losses and helps to increase shelf life.

Vegetable Processing Units

Onions, tomatoes, carrots, potatoes, spinach, and peas are dehydrated for ready-to-cook meals, instant soups, spice blends, and powdered food products. Dehydrated vegetables are lightweight, easy to store, and ideal for bulk transport.

Herbs and Spices Drying

A food dehydrator machine. It can also be used for spices like chili, turmeric, ginger, and garlic. Proper dehydration preserves aroma, color, and medicinal properties.

Key Features of Our Food Dehydrator Machine

Our food dehydrators are made with cutting-edge technology and components that are built to last, serviced for small businesses, commercial kitchens, and large food processing units.

1. Advanced Food Drying Technology

A state-of-the-art food dehydrator machine with hot air circulation improves dehydrating efficiency. It preserves the food quality by keeping the nutrients, color, and flavor intact.

2. All Stainless Steel Design

The machine features food-grade, stainless steel construction. It is corrosion-resistant, easy to clean, and safe to use, providing a long service life.

3. Exact Temperature Control

Our dehydration machine includes precise temperature control, which allows the user to set the heat for different food types like fruits, vegetables, herbs, and spices. This precision in temperature control, in turn, produces very consistent and high-quality results\

Benefits of a Food Dehydrator Machine

A food dehydrator machine is an important tool for naturally preserving food without losing its quality, taste, and nutrition. They are commonly used in food processing units, commercial kitchens, and manufacturing industries because of their high efficiency and versatility. Here are some food dehydrator machine benefits.

1. Increases Food’s Shelf Life

One large benefit of a food dehydrator is that it removes moisture from your food, which in turn reduces bacteria and mold growth. This also greatly extends the shelf life of your fruits, vegetables, herbs, and other types of food without the use of chemical preservatives

2. Preserves Nutritional Value

Unlike traditional drying methods, food dehydrator machines use controlled temperature and air flow to capture vital vitamins, minerals, and natural enzymes. This makes for healthier and more nutritious dried food products.

3. Preserves Taste and Color

Gentle dehydration retains the natural flavor, scent, and color of the food. This enhances the appeal of dried foods and elevates the overall quality of the product

Summary

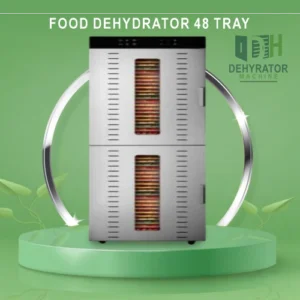

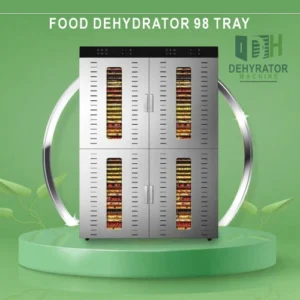

Food dehydrators, which use controlled heat and air flow to dry out moisture, thus naturally preserving fruits, vegetables, herbs, and spices,s which in turn extends the shelf life of the products while at the same time preserving taste, color, and nutrition. These machines,s which are used in food processing industries for snacks, ready-to-cook foods, spice drying, and bulk storage, have stainless steel construction, precise temperature control, and advanced hot air circulation. We also see the benefits of the extended shelf life of products without chemicals, better nutrient preservation, and consistent high-quality output. For large-scale production, which is continuous, we have industrial models (60 120 trays) which are priced around ₹1,50,000, ₹3,50,000

Reviews

There are no reviews yet.